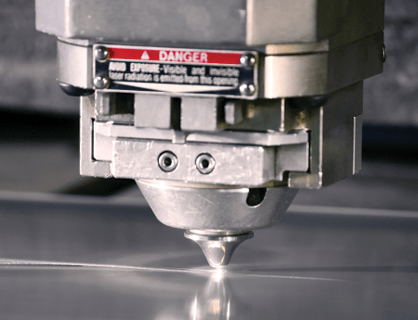

Many different products can be made using these shaping processes, and one such product is extruded aluminum tubing. Extruded aluminum tubing is created by heating up an aluminum blank and forcing it through a die, which removes material to shape the blank into its final form. Read More…

Serving the aluminum extrusions world from Cleveland, Ohio, Talan Products specializes in a range of aluminum extrusion products and services.

Quality Stamping & Tube Corp has been a leader in the aluminum extrusions and metal stamping industries for over 40 years. We attribute our success to our in-house die-making capabilities and wide range of extruded parts. All of our products are manufactured with quick turnaround and made to be high quality and durable. Our aluminum extrusions follow guidelines of up to 6 inches in diameter and...

Since 1986, GSH Industries has offered on time delivery and competitive pricing. With over 40,000 square feet of manufacturing, we offer aluminum extrusion products and services.

Dajcor Aluminum is the leading North American supplier of extruded, fabricated/machined, anodized and assembled components to the automotive, renewable energy, transportation, rail, marine, building trades, military, medical architectural and wall partition systems, office furniture, emergency vehicle and consumer product industries. Dajcor is an aluminum extrusion company with complete value add ...

More Extruded Aluminum Tubing Manufacturers

When the product has come out of the die, it is cooled and then stretched to get rid of any twisting or changes that may have occurred during the cooling process. The harder the extruded aluminum gets, the stronger it becomes. In some instances, the aluminum is allowed to harden at room temperature, but more often temperature controlled rooms are used to more quickly cool the aluminum tubing.

There are two main types of structural aluminum tubing. The first splits the aluminum tube and reseals it under high temperature and pressure conditions. The resealing is also facilitated by metallurgical welds. The seam is also created during this process and in some cases can be seen by the naked eye. Tubes made with this method are not ideal for the transportation of gases or liquids under high pressure because of the possible breakage or leak of the seam.

The second process entails pushing a hollow billet through a die. This process does not create a seam and can be used to transport or store pressurized gases and liquids. Extruded aluminum tubes are used in different industries including transportation, marine, solar and renewable energy, construction, military and compressed gas storage. Some aluminum tubes are extruded with other alloys and in order to identify the kind of extruded aluminum tube to buy, the aluminum industry created a four-digit system to specify the components of a particular tube.

The first number tells what the major alloying element is, the second tells whether there was a modification in the basic alloy, the third and fourth tell the specific alloy. 1 represents aluminum, 2 represents copper, 3 represents manganese, 4 represents magnesium, 6 represents magnesium and silicone, and 7 represents zinc.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Nickel

Nickel Magnets

Magnets Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services