Universal Molding Company

Universal Molding CompanyRequest A Quote

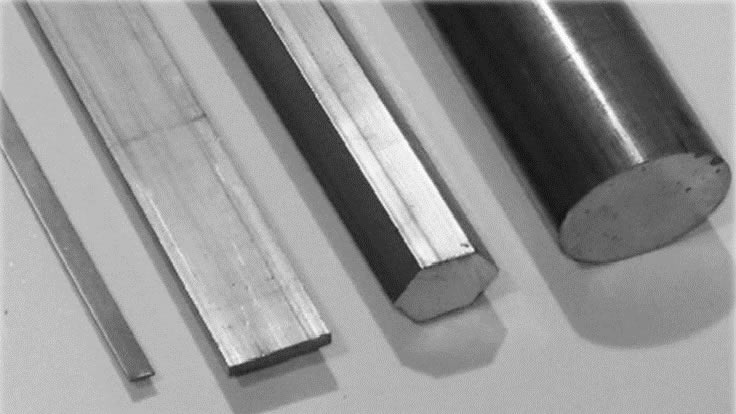

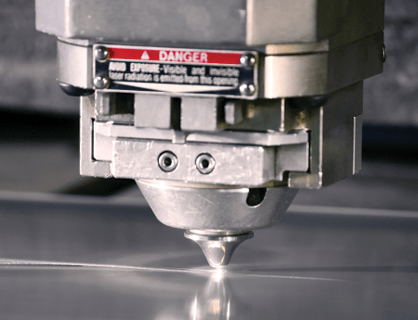

Downey, CA | 562-940-0300Universal Molding Company is a reputable manufacturer and provider of aluminum extrusions products and services, specializing in the production of high-quality custom aluminum profiles. With a strong focus on precision, quality, and customer satisfaction, Universal Molding Company has established itself as a trusted leader in the industry. Our company operates state-of-the-art manufacturing facilities equipped with advanced extrusion technology and machinery, allowing us to produce a wide range of aluminum extrusions that cater to the diverse needs of our customers. We serve various industries, including automotive, aerospace, electronics, construction, and consumer goods sectors, delivering tailored solutions that meet the highest standards. Product Capabilities: Universal Molding Company offers a comprehensive range of aluminum extrusions products designed to deliver exceptional performance, durability, and versatility. Our product capabilities include, but are not limited to: Custom Aluminum Profiles: We specialize in the design and manufacturing of custom aluminum profiles to meet specific customer requirements. Our experienced team of engineers and designers collaborates closely with clients to understand their needs and develop customized extrusions that meet precise specifications. We have the expertise to produce profiles with complex geometries, intricate features, and tight tolerances to support a wide range of applications. Standard Aluminum Profiles: In addition to custom profiles, Universal Molding Company provides a wide selection of standard aluminum profiles, including angles, channels, tubes, bars, and rods. These profiles are available in various sizes, shapes, and alloys, offering versatility and compatibility with diverse applications. Our standard profiles are manufactured with precision and meet industry specifications. Value-Added Components: We offer value-added components such as brackets, connectors, and fasteners that complement our aluminum extrusions. These components are designed to provide easy installation, enhanced functionality, and seamless integration with our extrusion products. Our value-added components are manufactured to the same high standards as our aluminum profiles. Service Capabilities: Universal Molding Company is committed to providing exceptional services that complement our product offerings. Our service capabilities are designed to support customers throughout the entire process, from design to delivery. Our service offerings include: Design and Engineering Support: Our skilled team of engineers and designers provides comprehensive design and engineering support to customers. We work closely with clients to understand their specific needs, develop innovative solutions, and optimize the performance of aluminum extrusions. Using advanced design software and simulation tools, we ensure accuracy, functionality, and manufacturability of the final product. Manufacturing Excellence: Universal Molding Company maintains stringent quality control measures throughout the manufacturing process. Our advanced extrusion technology, combined with strict quality assurance procedures, ensures the production of extrusions with precise dimensions, excellent surface finish, and consistent quality. We have the capacity to handle both small and large-scale production runs. Finishing and Surface Treatment: We offer a range of finishing options for our aluminum extrusions, including anodizing, powder coating, painting, and custom finishes. These surface treatments enhance the appearance, corrosion resistance, and durability of the extrusions, making them suitable for various applications and environments. Fabrication and Assembly: Universal Molding Company provides fabrication and assembly services to deliver fully finished and ready-to-use products to our customers. Our capabilities include cutting, drilling, bending, machining, and assembly, ensuring that our extrusions are customized to meet specific project requirements. Logistics and Supply Chain Management: We have a robust logistics network in place to ensure efficient production and timely delivery of our products. We work closely with trusted logistics partners to streamline the supply chain, optimize inventory management, and provide reliable shipping options. Our efficient logistics processes ensure that customers receive their orders promptly and in optimal condition. Universal Molding Company is dedicated to exceeding customer expectations by delivering top-quality aluminum extrusions and exceptional service. With our technical expertise, commitment to precision, and customer-centric approach, we strive to be the preferred partner for businesses seeking customized aluminum extrusion solutions.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Nickel

Nickel Magnets

Magnets Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services