Offshore Direct Metals, Inc.

Offshore Direct Metals, Inc.Request A Quote

Orlando, FL | 855-272-3889http://www.odmetals.com/product/custom-aluminum-extrusions

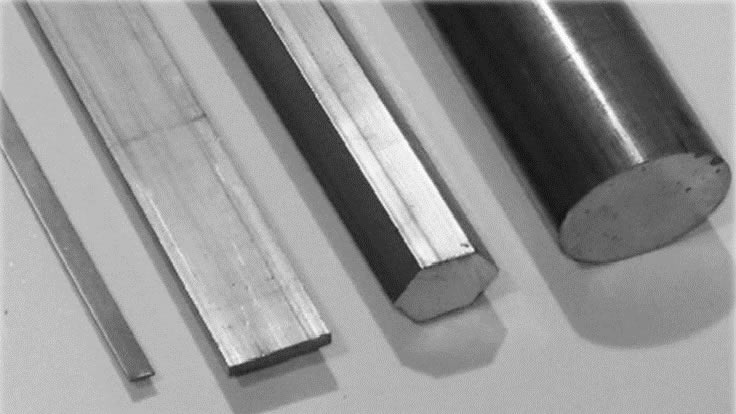

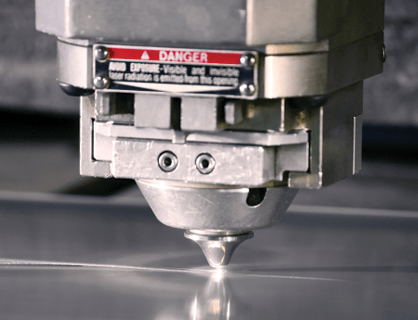

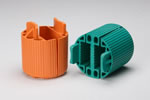

Offshore Direct Metals, Inc. is a reputable company specializing in the production and supply of aluminum extrusions. With a strong focus on quality, reliability, and customer satisfaction, Offshore Direct Metals has established itself as a trusted supplier in the industry. At Offshore Direct Metals, they understand the unique needs and specifications of their customers. With their advanced manufacturing facilities and expertise in aluminum extrusion processes, they are able to produce a wide range of high-quality extrusions to meet various industry requirements. Their extrusion capabilities cover a diverse range of profiles, sizes, and alloys, ensuring that customers can find the perfect solution for their specific applications. The company works closely with their customers to understand their project requirements and provide tailored solutions. Their experienced team of engineers and technicians utilize state-of-the-art technologies and techniques to deliver extrusions that meet the highest industry standards. Whether it's standard profiles or custom designs, Offshore Direct Metals has the capabilities to manufacture extrusions with exceptional precision, consistency, and finish. Offshore Direct Metals offers an extensive catalog of aluminum extrusion profiles, including angles, channels, tubes, bars, and more. They also specialize in providing custom extrusions based on customer specifications. Their team collaborates closely with clients to design and develop unique profiles that meet their specific needs. By leveraging their engineering expertise and advanced manufacturing capabilities, they can create extrusions that offer optimal functionality, aesthetics, and performance. In addition to their aluminum extrusion capabilities, Offshore Direct Metals offers a range of value-added services to enhance the versatility and usability of their products. These services include precision cutting, machining, fabrication, finishing, and assembly. They have the expertise and equipment to perform precise cuts, drill holes, add surface treatments, and provide various other secondary operations. By offering these value-added services, Offshore Direct Metals ensures that customers receive extrusions that are ready for immediate use in their applications. Quality is a top priority at Offshore Direct Metals. They have implemented rigorous quality control processes throughout their manufacturing operations to ensure that every extrusion meets the highest standards. From the selection of premium quality aluminum alloys to the inspection of finished products, they maintain strict adherence to quality standards and specifications. Their dedicated quality assurance team conducts thorough inspections and tests to verify the dimensional accuracy, surface finish, and mechanical properties of each extrusion. Offshore Direct Metals serves a wide range of industries, including aerospace, automotive, construction, marine, and more. Their aluminum extrusions find applications in structural components, architectural features, transportation systems, machinery, and various other sectors. With their commitment to delivering top-quality products, customized solutions, and excellent customer service, Offshore Direct Metals has built strong relationships with customers around the world. In summary, Offshore Direct Metals, Inc. is a trusted supplier of aluminum extrusions, offering a comprehensive range of products and services. With their advanced manufacturing capabilities, customization options, and commitment to quality, they provide customers with high-quality extrusions that meet their specific requirements. By choosing Offshore Direct Metals, customers can expect reliable products, tailored solutions, and exceptional support throughout their project journey.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Nickel

Nickel Magnets

Magnets Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services