ALMAG Aluminum Inc.

ALMAG Aluminum Inc.Request A Quote

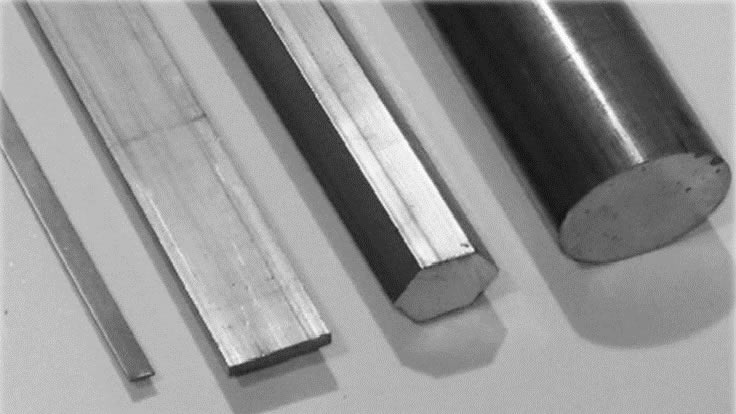

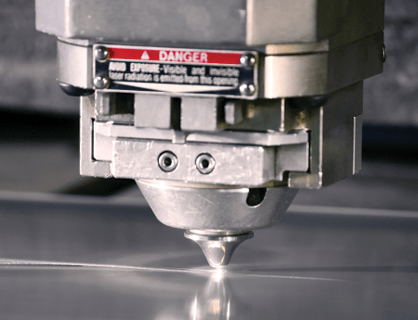

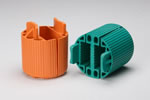

Brampton, ONALMAG Aluminum Inc. is a renowned industry leader in the manufacturing of high-quality aluminum extrusions. With a strong commitment to innovation, excellence, and customer satisfaction, ALMAG has established itself as a trusted provider of aluminum extrusion products and services. The company boasts state-of-the-art facilities equipped with the latest technology and machinery, allowing them to deliver precise and efficient aluminum extrusions. ALMAG's team of skilled engineers and technicians work closely with clients to understand their specific requirements and collaborate on the design and production of customized aluminum extrusions. From simple profiles to complex geometries, ALMAG has the expertise and capabilities to deliver superior results. ALMAG offers a comprehensive range of aluminum extrusion profiles, including standard shapes, custom designs, and intricate profiles. They utilize advanced extrusion techniques, such as precision extrusion and micro-extrusion, to produce aluminum profiles with tight tolerances, exceptional surface finishes, and precise dimensions. With their versatile extrusion process, ALMAG can create profiles of various sizes, shapes, and complexities, catering to diverse applications and industries. In addition to their manufacturing capabilities, ALMAG provides a wide range of value-added services to support their customers throughout the entire process. Their team of experts assists clients with product development, design optimization, prototyping, and finishing options. They work closely with clients to ensure that every project meets the desired specifications and exceeds expectations. ALMAG's aluminum extrusion products find applications in various industries, including automotive, aerospace, construction, electronics, and more. These extrusions are widely used in structural components, heat sinks, frames, enclosures, and other applications where lightweight, corrosion-resistant, and durable materials are required. ALMAG understands the unique demands of each industry and works closely with clients to deliver aluminum extrusions that meet their specific requirements. Quality is paramount at ALMAG, and they have implemented rigorous quality control measures throughout the manufacturing process. Every aluminum extrusion undergoes stringent inspection and testing to ensure it meets or exceeds industry standards. ALMAG's commitment to quality ensures that their customers receive products of the highest quality and performance. ALMAG is also dedicated to sustainability and environmental responsibility. They employ eco-friendly practices in their operations, such as recycling aluminum scraps and optimizing energy consumption. By prioritizing sustainability, ALMAG contributes to the preservation of the environment and the reduction of carbon footprint. Customer satisfaction is at the forefront of ALMAG's priorities. They are known for their exceptional customer service, timely delivery, and effective communication throughout the project. ALMAG's responsive and knowledgeable team is always available to address customer inquiries, provide technical support, and offer solutions to meet their specific needs. In summary, ALMAG Aluminum Inc. is a leading manufacturer of aluminum extrusions, known for their commitment to innovation, quality, and customer satisfaction. With their advanced facilities, technical expertise, and wide range of services, ALMAG delivers customized aluminum extrusions that meet the highest standards. From design to production, ALMAG ensures that every project is handled with precision and care. Customers can trust ALMAG to provide them with top-quality aluminum extrusion products and exceptional service.

Leading Aluminum Extrusion Manufacturers

More Aluminum Extrusion Manufacturers

Additional Categories: Industrial Balers, Boilers

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Nickel

Nickel Magnets

Magnets Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services