Momentum Manufacturing Group

Momentum Manufacturing GroupRequest A Quote

Georgetown, MAMomentum Manufacturing Group is a highly respected company specializing in the production and distribution of top-quality aluminum extrusions. With a strong focus on innovation, precision, and customer satisfaction, Momentum Manufacturing Group has earned a reputation as a leading provider of aluminum extrusion solutions. They offer a comprehensive range of products and a wide array of service capabilities to meet the diverse needs of their customers. At Momentum Manufacturing Group, their aluminum extrusion products are manufactured using state-of-the-art technology and advanced manufacturing processes. They work with high-quality aluminum alloys to produce extrusions that possess exceptional strength, durability, and corrosion resistance. Their skilled engineers and technicians ensure that each extrusion is meticulously crafted to meet the exact specifications and requirements of their customers. The product portfolio of Momentum Manufacturing Group includes a variety of standard and custom aluminum extrusions. They offer a wide range of profiles, shapes, sizes, and finishes to accommodate different applications and industries. Whether customers require standard shapes or intricate custom designs, Momentum Manufacturing Group has the capabilities to deliver tailored solutions. Their team of experts collaborates closely with customers to understand their unique requirements and provide expert guidance throughout the design and manufacturing process. In addition to their extensive product range, Momentum Manufacturing Group offers a comprehensive suite of value-added services. Their advanced facilities are equipped with cutting-edge machinery and equipment for precision cutting, drilling, machining, and finishing. They also provide secondary operations such as welding, bending, punching, and assembly. These service capabilities enable Momentum Manufacturing Group to offer customers a one-stop solution for their aluminum extrusion needs, saving time and resources. Quality is of utmost importance at Momentum Manufacturing Group. They have implemented stringent quality control measures at every stage of the manufacturing process to ensure that their extrusions meet the highest industry standards. From material selection to final inspection, their team of quality experts conducts rigorous tests and inspections to guarantee the reliability and consistency of their products. This commitment to quality ensures that customers receive aluminum extrusions that are of superior quality and performance. Momentum Manufacturing Group takes pride in their customer-centric approach. They are dedicated to providing exceptional customer service and support. Their team of professionals works closely with customers to understand their unique requirements, offer technical expertise, and provide personalized solutions. They are committed to delivering projects on time, within budget, and to the complete satisfaction of their customers. With their extensive industry experience and expertise, Momentum Manufacturing Group serves a wide range of industries, including construction, automotive, aerospace, electronics, and more. Their aluminum extrusions are used in architectural projects, transportation components, electrical enclosures, machinery parts, and various other applications where lightweight, durable, and versatile solutions are required. In summary, Momentum Manufacturing Group is a reputable provider of high-quality aluminum extrusions, offering a comprehensive product range, customization capabilities, stringent quality control processes, and exceptional customer service. Their commitment to innovation, precision, and customer satisfaction sets them apart in the industry. For customers seeking reliable and precise aluminum extrusion solutions, Momentum Manufacturing Group is the trusted partner of choice.

Alloy Suppliers

Alloy Suppliers Aluminum

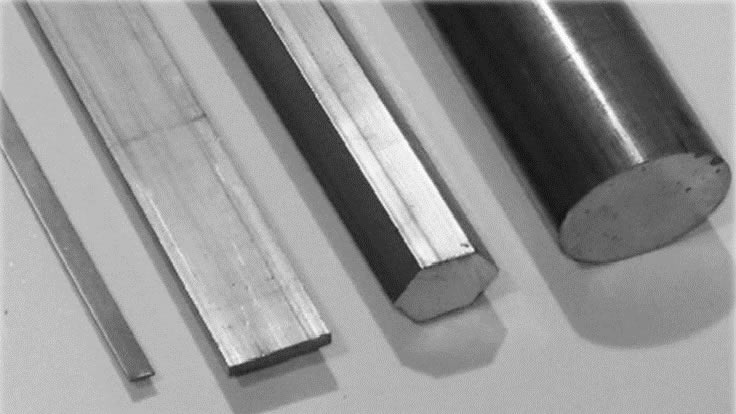

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Nickel

Nickel Magnets

Magnets Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

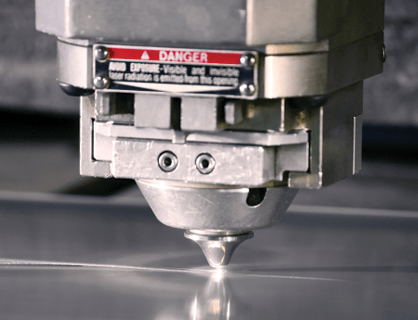

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

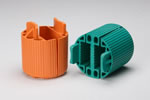

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services