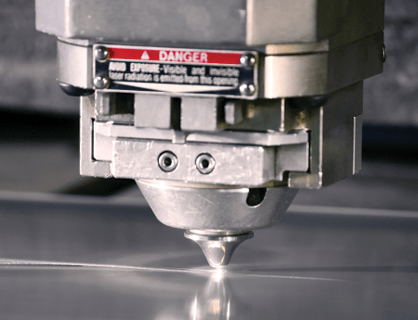

The aluminum extrusion process is a precise method for creating aluminum profiles by forcing soft aluminum billets through a die using a hydraulic press or ram. The force of squeezing the softened aluminum through the die profile enhances its strength and durability. Aluminum extrusion can be hot or cold, determined by the type of aluminum and how the extrusion is completed. Read More…

Since 1948, Johnson Brothers has been a leader in the aluminum roll forming industry. Our tooling can form different shapes with multiple bends & double thicknesses making a stronger part. Choose your type of outside edge, including hemmed designs. Our manufacturing procedure can take your part from concept to achievement. Please contact us today with any questions.

Quality Stamping & Tube Corp has been a leader in the aluminum extrusions and metal stamping industries for over 40 years. We attribute our success to our in-house die-making capabilities and wide range of extruded parts. All of our products are manufactured with quick turnaround and made to be high quality and durable. Our aluminum extrusions follow guidelines of up to 6 inches in diameter and...

Since 1986, GSH Industries has offered on time delivery and competitive pricing. With over 40,000 square feet of manufacturing, we offer aluminum extrusion products and services.

Dajcor Aluminum is the leading North American supplier of extruded, fabricated/machined, anodized and assembled components to the automotive, renewable energy, transportation, rail, marine, building trades, military, medical architectural and wall partition systems, office furniture, emergency vehicle and consumer product industries. Dajcor is an aluminum extrusion company with complete value add ...

More Aluminum Extruder Manufacturers

Extruded Aluminum Shapes: Versatility in Design and Application

Aluminum extrusion is a manufacturing process that forces aluminum alloy material through a shaped die to create profiles with a consistent cross-section. This technology allows for the creation of a wide range of extruded aluminum shapes tailored to specific engineering and architectural requirements. Whether for industrial, commercial, or residential use, the adaptability and design flexibility of extruded shapes make them an ideal choice for countless applications. As industries seek lightweight, durable, and cost-effective solutions, extruded aluminum profiles continue to be a preferred option across sectors.

Common Types of Aluminum Extrusions

Understanding the different types of extruded shapes helps you select the right product for your project. Explore the major categories below to discover which aluminum extrusion profiles meet your needs.

Angles

Aluminum angles are among the most commonly used extruded profiles due to their simplicity and strength. Available with either sharp or rounded corners, they are manufactured in various lengths and thicknesses to accommodate a wide range of structural and framing requirements. Their L-shaped cross-section provides excellent reinforcement for frames, supports, and brackets in construction, machinery, and shelving systems. If you're searching for reliable support elements or need to reinforce corners, consider aluminum angles for your next project.

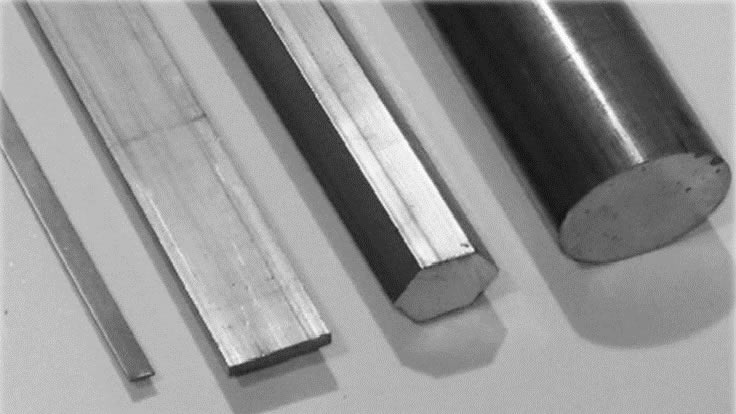

Bars

Extruded aluminum bars are produced in rectangular, square, or hexagonal shapes, offering robust solutions for structural support. The precise control of thickness during extrusion ensures that these bars meet stringent standards for strength and dimensional accuracy. Typical uses include load-bearing supports, machine components, and custom-fabricated parts for the automotive and manufacturing industries. Are you evaluating which aluminum bar profile is best suited for your application? Our detailed guide can help you compare standard and custom options.

Channels

Aluminum channels are extruded profiles with a U-shaped cross-section, offering versatile solutions for a variety of structural and decorative applications. These channels are widely used as edging for windows and doors, structural reinforcements, handrails, cable management systems, and architectural accents. Their open design makes them ideal for enclosing and protecting wiring or providing discreet support in furniture and building frameworks. Looking to integrate aluminum channels into your next project? Learn about sizing, finishes, and compatibility with other materials.

I Beams

Aluminum I beams feature a distinctive "I" shaped cross-section, delivering high tensile strength and structural stability while minimizing material weight. Used extensively in modern construction, infrastructure projects, and industrial machinery, aluminum I beams are favored for their ease of installation, corrosion resistance, and ability to support heavy loads without excessive weight. Are you comparing steel versus aluminum I beams for your design? Review our comprehensive comparison to make an informed decision.

Tees

Aluminum tees are T-shaped extrusions engineered with either sharp or rounded edges. They are often used to seal edges, provide a finished appearance, or cover rough surfaces on panels, walls, or flooring. Their design also offers reliable reinforcement for frame assemblies and partitions. Considering adding a clean finish or extra support to your structure? Tees may be the ideal solution for your needs.

Tubes

Extruded aluminum tubes are increasingly popular in industries requiring lightweight, corrosion-resistant conduits or supports. Available in both round and rectangular profiles, aluminum tubing is commonly used for transporting fluids, connecting mechanical devices, and providing sturdy frameworks in automotive, aerospace, marine, and architectural projects. Aluminum extruded tubing comes in a vast array of diameters, wall thicknesses, and custom finishes to accommodate any application. Not sure which tube specification fits your requirements? Explore our technical resources for guidance on material selection, sizing, and finishing options.

Zees

Extruded aluminum Z shapes—commonly referred to as zees—feature a distinctive "Z" profile, making them highly adaptable for applications such as rails, clips, mounting supports, and framework connectors. With variable flange widths and thicknesses, zees can be customized to meet unique engineering constraints or design aesthetics. Their versatility makes them essential in sectors ranging from transportation to architectural metalwork. Need a custom solution for your project? Contact us for tailored Z-shape extrusion designs.

Specialty and Custom Aluminum Extrusions

Beyond standard profiles, aluminum extrusion manufacturers offer specialty and custom-designed shapes to address unique requirements. These may include complex multi-chamber profiles for improved thermal management, intricate decorative trims, or specially engineered connectors for modular assemblies. If your application demands a non-standard profile, partnering with a custom aluminum extruder ensures optimal fit, functionality, and performance.

Aluminum Alloys for Extrusion: Selecting the Right Material

The term "aluminum" in extrusion encompasses a wide variety of alloys, each formulated for specific mechanical properties, corrosion resistance, and workability. Aluminum alloys are distinguished by a four-digit numerical designation that reveals their composition and suitability for different extrusion processes. The two primary categories are cast aluminum alloys—which have a lower melting point and are easier to shape but less strong—and wrought aluminum alloys, which are stronger, more resilient, and ideal for demanding applications.

Understanding the differences between cast and wrought aluminum is crucial for manufacturers, engineers, and buyers. Cast aluminum alloy numbers include a decimal point between the third and fourth digit (e.g., 356.0), while wrought alloys use a four-digit system without a decimal (e.g., 6061). This simple distinction helps identify the material type and informs your selection based on project needs. The choice of aluminum alloy for extrusion depends on factors such as strength requirements, machinability, corrosion resistance, surface finish, and intended application.

Popular Aluminum Alloys Used in Extrusion

Aluminum 1100

Aluminum 1100 is considered commercially pure aluminum (99% minimum). Renowned for its exceptional ductility, softness, and corrosion resistance, 1100 alloy is easily extruded into numerous shapes and is often employed in chemical equipment, food handling, and decorative applications. Need pure aluminum for your project? 1100 may be the optimal choice for forming, spinning, and lightweight assemblies.

Aluminum 3003

Composed primarily of aluminum and manganese, Aluminum 3003 offers greater strength than 1100 while retaining excellent workability and corrosion resistance. It is commonly extruded for use in heat exchangers, cooking utensils, storage tanks, and architectural trim. Balancing formability and strength, 3003 alloy is a go-to material for moderate-load, general-purpose applications. Looking for a versatile and dependable alloy? 3003 is widely available and cost-effective.

Aluminum 6063

Aluminum 6063, an alloy of magnesium and silicon, is referred to as "architectural aluminum" due to its outstanding surface finish and ability to be extruded into intricate, precise shapes. It is favored for decorative trims, window and door frames, and curtain wall systems. 6063 extrusions can be anodized for enhanced corrosion resistance and aesthetic appeal. Are you specifying materials for visible or decorative components? Consider 6063 for superior surface quality and design flexibility.

Aluminum 6061

Aluminum 6061 is a versatile, high-strength alloy containing magnesium and silicon. With a tensile strength of 35,000 to 38,000 psi, it is widely used for structural components, automotive frames, pipelines, and aerospace parts. 6061 offers excellent machinability, weldability, and corrosion resistance, making it ideal for high-stress applications. If you're weighing material options for demanding environments, 6061 is a proven performer across industries.

Aluminum 7075

Aluminum 7075 is one of the strongest commercially available aluminum alloys, with a composition that includes zinc, copper, and magnesium along with trace elements. It rivals low-grade steels in strength while delivering significant weight savings and corrosion resistance. 7075 is commonly selected for critical aerospace, defense, and performance automotive components where durability and fatigue resistance are paramount. Need maximum strength and longevity? 7075 delivers elite performance in extreme conditions.

How to Choose the Right Aluminum Alloy for Extrusion

- Application requirements: Consider intended use, load-bearing needs, and environmental exposure.

- Formability and machinability: Select alloys that accommodate required fabrication techniques (bending, cutting, welding).

- Corrosion resistance: For outdoor or marine environments, prioritize alloys with superior resistance to oxidation and weathering.

- Surface finish and aesthetics: Architectural or decorative applications may require alloys that accept anodizing or painting.

- Cost-effectiveness: Balance material properties with budget constraints to optimize both performance and price.

Still unsure which alloy fits your needs? Contact our extrusion experts for personalized recommendations and technical support.

Advantages of Aluminum Extrusion: Unlocking Design and Manufacturing Potential

The aluminum extrusion process offers a host of benefits that make it one of the most efficient and adaptable manufacturing solutions available. By leveraging modern die technology and advanced alloy formulations, manufacturers can create custom extruded parts with exceptional accuracy and repeatability. Explore the top advantages below to see why aluminum extrusion is a leading choice for product designers and engineers:

- Superior strength-to-weight ratio: Aluminum extrusions offer high mechanical strength while remaining lightweight, making them ideal for applications where reducing weight is critical (e.g., transportation, aerospace, and portable equipment).

- Material versatility: A wide range of aluminum alloys and tempers can be selected to suit performance, appearance, and environmental requirements.

- Unmatched design flexibility: The ability to create complex, custom profiles supports innovative product development and rapid prototyping.

- Corrosion resistance: Aluminum naturally forms a protective oxide layer, enhancing durability in harsh or outdoor environments.

- Thermal and electrical conductivity: Aluminum extrusions efficiently transfer heat and electricity, making them suitable for heat sinks, enclosures, and electrical components.

- Cost-effective production: Extrusion tooling is generally less expensive than other metal-forming processes, and rapid production cycles reduce lead times and overall costs.

- Recyclability: Aluminum is one of the most recycled metals globally, supporting sustainability initiatives and reducing environmental impact.

Key Applications of Aluminum Extrusions

Aluminum extrusions are integral to a vast array of industries and products. Here are some of the most prominent applications:

- Construction and architecture: Window frames, curtain walls, structural supports, railings, and sunshades.

- Automotive and transportation: Vehicle frames, roof rails, engine blocks, and heat exchangers.

- Aerospace and defense: Aircraft seat tracks, fuselage components, satellite structures, and military equipment.

- Industrial machinery: Conveyor systems, workstations, machine guards, and automation equipment.

- Consumer products: Furniture, lighting fixtures, electronics enclosures, and sports equipment.

- Renewable energy: Solar panel frames, wind turbine parts, and energy-efficient building systems.

Comparing Aluminum Extrusion to Other Metal Forming Methods

When evaluating manufacturing options, it's vital to understand how aluminum extrusion compares to other metal forming processes such as casting, rolling, or stamping. Key advantages include faster turnaround times, the ability to produce highly customized profiles, and reduced need for secondary machining. Additionally, aluminum extrusion's inherent material efficiency and low waste generation make it a preferred option for eco-conscious manufacturers. Need help choosing between extrusion and alternative processes?

How to Choose an Aluminum Extruders Manufacturer

Partnering with the right aluminum extruder is essential to achieving the best results for your project. Here are key decision factors to consider when selecting an aluminum extrusion supplier:

- Experience and expertise: Evaluate the manufacturer's history in producing aluminum extrusions for your industry.

- Capabilities and equipment: Ensure the supplier offers the required profile dimensions, alloy selections, finishing options, and value-added services (e.g., cutting, machining, anodizing).

- Quality assurance: Ask about quality control processes, certifications (such as ISO 9001), and testing protocols.

- Lead times and responsiveness: Reliable communication and timely delivery are crucial for project success.

- Customization and engineering support: Look for manufacturers who can assist with design optimization and prototyping.

- Pricing and minimum order quantities: Balance cost considerations with the supplier’s ability to meet your volume requirements.

To ensure a positive outcome when purchasing aluminum extruders or custom extruded aluminum products, compare at least six companies using our list of aluminum extruders suppliers. Each manufacturer’s business profile page highlights their areas of expertise, capabilities, and unique offerings. Use the integrated contact forms to request detailed quotes, technical information, or samples directly from suppliers.

Our patented website previewer enables you to quickly review each manufacturer's specialties and value propositions. Once you’ve identified promising partners, use our simple RFQ (Request for Quote) form to contact multiple aluminum extrusion companies simultaneously. This streamlined process helps you gather competitive quotes, compare lead times, and ultimately select the best aluminum extruder for your project’s needs.

Questions to Ask When Sourcing Aluminum Extrusions

- What alloy and temper options are available for my required profile?

- Can you provide samples or prototypes for testing?

- What surface finishing and secondary processing services do you offer?

- How do you ensure dimensional accuracy and quality control?

- What is your typical lead time for custom or large-volume orders?

- Are there design guidelines or recommendations to optimize my extrusion?

Ready to take the next step? Contact multiple aluminum extrusion suppliers today to receive tailored quotes and expert advice on your project requirements.

Frequently Asked Questions about Aluminum Extrusion

- What is the minimum order quantity for custom aluminum extrusions?

Minimum order quantities (MOQs) vary by manufacturer and profile complexity. Standard profiles may be available with lower MOQs, while custom designs typically require higher volumes. Check with your chosen supplier for specific requirements. - How long does it take to produce aluminum extrusions?

Lead times depend on the complexity of the profile, die manufacturing, finishing processes, and order volume. Simple profiles may be delivered in as little as 2-4 weeks, while complex or highly customized extrusions can take longer. - What finishing options are available for aluminum extrusions?

Common finishes include anodizing, powder coating, painting, sandblasting, and mechanical polishing. Each finish offers unique benefits, from enhanced corrosion resistance to improved aesthetics. - Can aluminum extrusions be recycled?

Yes! Aluminum is 100% recyclable without loss of properties, making it a sustainable choice for eco-friendly manufacturing and construction projects. - Which industries use aluminum extrusions?

Key sectors include construction, transportation, aerospace, marine, electronics, furniture, and renewable energy.

Explore More on Aluminum Extrusion

Want to learn more about how aluminum extrusion can benefit your next project? Browse our in-depth resources on:

- How the aluminum extrusion process works

- Die design and manufacturing

- Finishing and surface treatment options

- Industry standards and certifications

- Case studies showcasing successful applications

Aluminum extrusion continues to shape industries with its unmatched combination of strength, flexibility, and efficiency. Whether you’re designing a new product, seeking structural solutions, or looking to optimize manufacturing, aluminum extrusions deliver proven value. Ready to find the right supplier or start your next project? Request a quote from leading aluminum extrusion manufacturers today.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Nickel

Nickel Magnets

Magnets Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services