Explore Our Aluminum Extrusions Gallery

Welcome to our Aluminum Extrusions Gallery! Here, you can click on the images below or the menu above to discover a wide range of high-performance aluminum extrusion manufacturers. Each category showcases aluminum extrusions used in various industries, ensuring top-quality products for diverse applications.

Aluminum Impact Extrusion – Metal Impact

Aluminum Extrusion – Michigan Extrusion Aluminum

Aluminum Extrusion – Telescoping – Silver City Aluminum

Aluminum Extrusion – Michigan Extrusion Aluminum

Aluminum Extrusion – Sanborn Tube

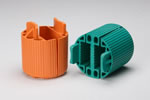

Aluminum Extrusion – Heat Sinks – Silver City Aluminum

Overview of Aluminum Extrusions

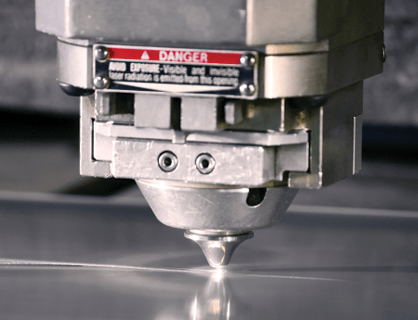

Aluminum extrusions are versatile and cost-effective solutions for a wide range of manufacturing needs. These extrusions are formed by forcing aluminum through a die, creating complex shapes with consistent dimensions. Ideal for use in industries such as automotive, aerospace, and construction, aluminum extrusions offer a lightweight and durable material with excellent corrosion resistance. By leveraging modern extrusion techniques, manufacturers can create products that meet precise specifications and offer superior performance in diverse applications.

Types of Aluminum Extrusions and Their Applications

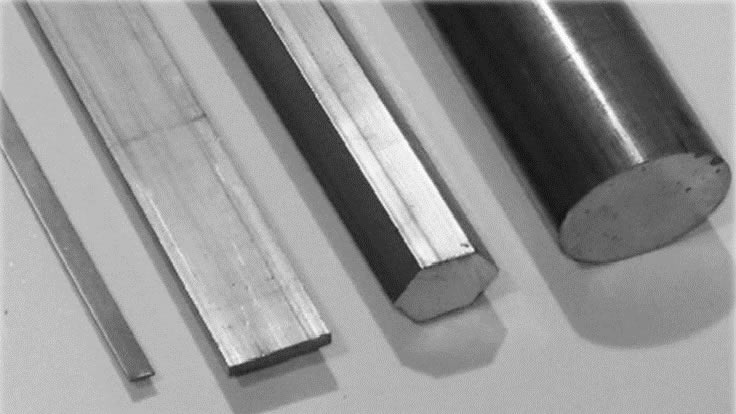

There are several types of aluminum extrusions, each designed for specific applications. These include structural shapes, such as bars and channels, and custom profiles used for intricate designs. Common applications of aluminum extrusions include building frames, window frames, heat sinks, and structural components for machinery and equipment. Whether for industrial or commercial use, aluminum extrusions provide exceptional strength-to-weight ratios, making them ideal for use in lightweight, high-strength designs.

Industries Served by Aluminum Extrusions

Aluminum extrusions are widely used across multiple industries due to their versatility. The automotive industry benefits from aluminum extrusions for producing lightweight, durable parts that improve fuel efficiency and performance. The construction sector uses extrusions for window frames, roofing components, and structural supports. Additionally, the aerospace, electronics, and telecommunications industries rely on aluminum extrusions for their high-strength, low-weight, and corrosion-resistant properties. This makes aluminum extrusions an essential material in modern manufacturing.

Benefits of Choosing the Right Aluminum Extrusion Manufacturer

Selecting the right aluminum extrusion manufacturer is crucial for achieving the best results in your projects. A reputable manufacturer can ensure that the extrusions meet precise dimensional tolerances, offer superior quality, and are produced with the latest technologies to enhance performance. Partnering with an experienced supplier also guarantees access to a range of customization options, including surface finishes, coatings, and specialty alloys. Choosing the right manufacturer can result in cost savings, improved product quality, and faster turnaround times for your projects.

Discover More Industry-Leading Suppliers

Need more options? Explore IQS Directory to find the most trusted manufacturers and suppliers in the industry.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Nickel

Nickel Magnets

Magnets Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services