Argyle Industries

Argyle IndustriesRequest A Quote

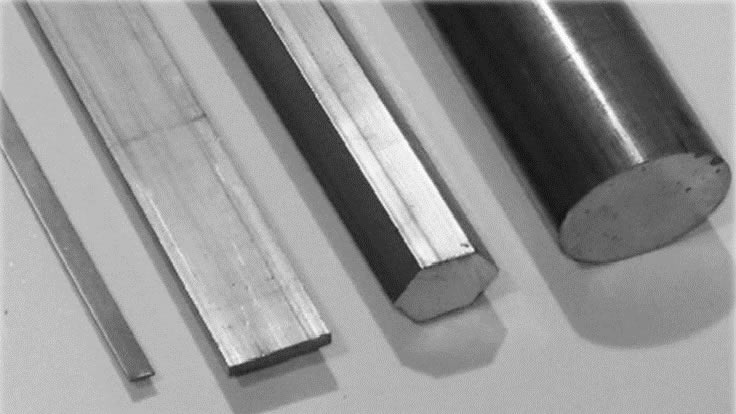

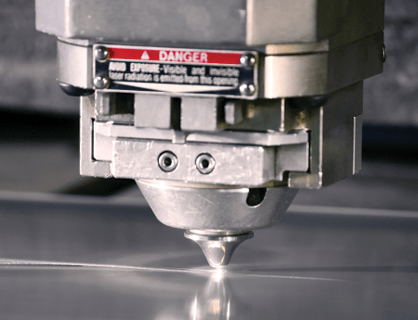

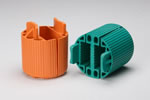

BRANCHBURG, NJArgyle Industries is a distinguished company specializing in the manufacturing and distribution of aluminum extrusions. With a strong presence in the industry, Argyle Industries has established itself as a reliable and innovative provider, renowned for its commitment to quality, precision, and customer satisfaction. Argyle Industries offers an extensive range of aluminum extrusions to cater to the diverse needs of its customers. The company collaborates with reputable mills and suppliers to ensure a consistent supply of high-quality aluminum materials. This enables Argyle Industries to provide a wide selection of standard and custom extrusions in various profiles, shapes, sizes, and finishes, meeting the specific requirements of each customer's project. One of the key strengths of Argyle Industries lies in its advanced manufacturing capabilities. The company operates a state-of-the-art facility equipped with modern extrusion presses and cutting-edge technology. With a team of experienced engineers and skilled technicians, Argyle Industries utilizes precision manufacturing techniques to produce aluminum extrusions of the highest quality. The company's commitment to continuous improvement and investment in advanced equipment ensures the production of precise, efficient, and reliable extrusions that meet or exceed industry standards. Customization is at the core of Argyle Industries' service capabilities. The company understands that each project is unique, and its team of experts excels in providing tailored solutions. Whether customers require assistance with product design, material selection, or custom extrusion development, Argyle Industries offers comprehensive support and guidance throughout the entire process. The company's ability to transform customer concepts into high-quality finished products sets them apart as a trusted partner in the industry. Argyle Industries is dedicated to delivering exceptional customer service. The company has a responsive and knowledgeable team that is committed to understanding and exceeding customer expectations. From initial inquiries to post-sales support, Argyle Industries provides personalized attention, timely communication, and prompt solutions. The company's customer-centric approach ensures a seamless experience and complete customer satisfaction. In addition to its manufacturing capabilities, Argyle Industries offers a range of value-added services to enhance the customer experience. The company provides precision cutting, machining, fabrication, and assembly services, allowing customers to receive extrusions that are ready for immediate use in their applications. Argyle Industries also offers various finishing options, including anodizing, powder coating, and custom colors, providing customers with the flexibility to achieve the desired aesthetics and protection for their aluminum extrusions. Quality is of utmost importance at Argyle Industries. The company follows stringent quality control measures at every stage of its operations, ensuring the consistency, precision, and durability of its aluminum extrusions. Argyle Industries is committed to meeting or exceeding industry standards and certifications, providing customers with extrusions that meet their exact specifications and deliver long-lasting performance. In summary, Argyle Industries is a respected provider of aluminum extrusions, known for its diverse product range, customization capabilities, advanced manufacturing, exceptional customer service, and commitment to quality. With its state-of-the-art facilities, value-added services, and customer-centric approach, Argyle Industries is the ideal partner for businesses seeking top-quality aluminum extrusions for their projects.

Leading Aluminum Extrusion Manufacturers

More Aluminum Extrusion Manufacturers

Additional Categories: Hydraulic Lifts, Hydraulic Press

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Nickel

Nickel Magnets

Magnets Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services