Basic Metals, Inc.

Basic Metals, Inc.Request A Quote

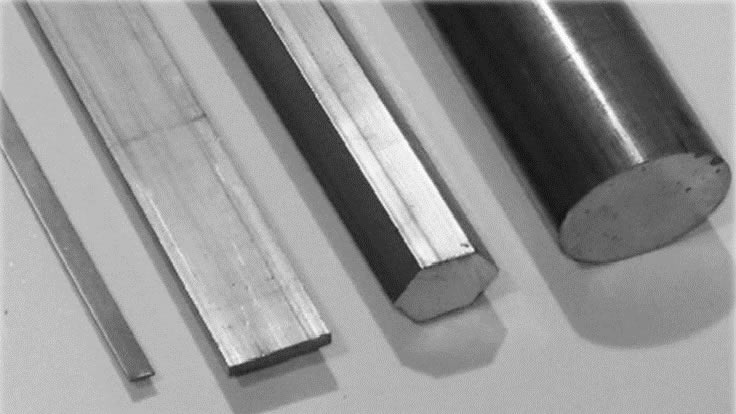

Germantown, WI | 262-255-9034Basic Metals, Inc. is a trusted and reliable company specializing in the production and distribution of aluminum extrusions. With a strong commitment to quality, precision, and customer satisfaction, Basic Metals has established itself as a leading provider of aluminum extrusion solutions. At Basic Metals, the focus is on delivering exceptional products that meet the highest industry standards. Their team of skilled professionals and engineers leverage their expertise and knowledge to produce aluminum extrusions of superior quality. Through the use of advanced extrusion technologies and state-of-the-art facilities, Basic Metals ensures precise and consistent extrusions that meet the specific requirements of their customers. The product range offered by Basic Metals is comprehensive and versatile. They provide a wide variety of aluminum extrusions, including standard shapes and custom profiles, to cater to diverse applications and industries. From simple angles and channels to complex geometric shapes, Basic Metals has the capabilities to deliver extrusions that match the unique specifications and design needs of their customers. With a strong focus on material quality, Basic Metals sources premium-grade aluminum alloys for their extrusions. These alloys, such as 6061 and 6063, offer excellent strength, corrosion resistance, and thermal conductivity, making them ideal for a wide range of applications. Whether it's for architectural projects, automotive components, electrical enclosures, or industrial equipment, Basic Metals' aluminum extrusions are designed to meet the highest performance standards. Basic Metals also prides itself on its comprehensive service capabilities. Their team of experienced professionals works closely with customers to understand their specific needs and provide tailored solutions. From design assistance and material selection to fabrication and finishing, Basic Metals offers a full suite of services to support their customers throughout the entire process. They have the expertise and resources to handle both small-scale and large-scale projects, ensuring timely and efficient delivery. In addition to their manufacturing capabilities, Basic Metals places great importance on quality control. They have implemented stringent quality assurance processes to ensure that each aluminum extrusion meets or exceeds industry standards. From material inspection to dimensional accuracy and surface finish, Basic Metals conducts thorough checks to guarantee the reliability and consistency of their products. Customer satisfaction is at the core of Basic Metals' business approach. They strive to build strong and long-lasting relationships with their customers by providing exceptional service, prompt communication, and reliable support. Their team is dedicated to addressing customer inquiries, providing technical expertise, and offering guidance throughout the entire project lifecycle. Basic Metals is committed to sustainability and environmental responsibility. They prioritize recycling and waste reduction practices in their manufacturing processes, ensuring minimal environmental impact. Additionally, they continuously invest in research and development to explore new techniques and technologies that enhance the efficiency and sustainability of their operations. In summary, Basic Metals, Inc. is a reputable company specializing in aluminum extrusions. With their focus on quality, precision, and customer satisfaction, they deliver a wide range of extrusion solutions tailored to meet the unique requirements of their clients. With comprehensive service capabilities, a diverse product range, and a commitment to sustainability, Basic Metals is a trusted partner for aluminum extrusion needs across various industries.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Nickel

Nickel Magnets

Magnets Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

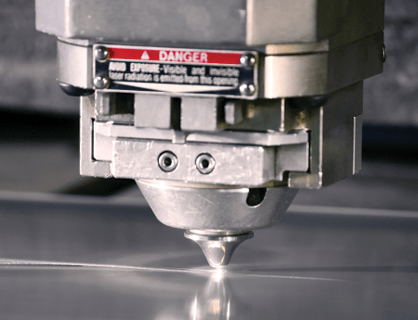

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

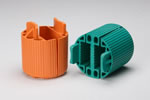

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services