C&C Manufacturing, Inc.

C&C Manufacturing, Inc.Request A Quote

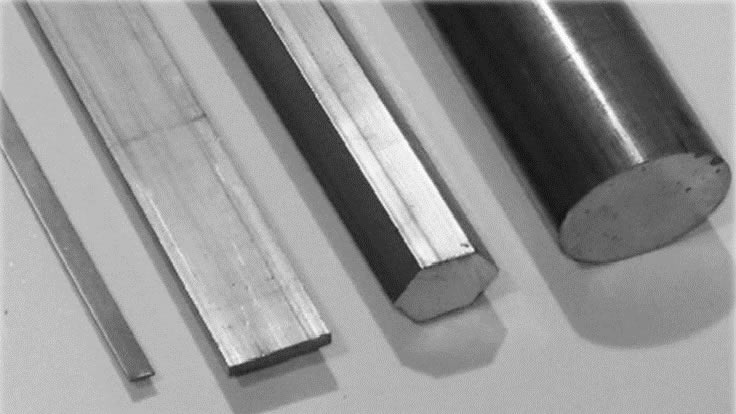

Sterling Heights, MIC&C Manufacturing, Inc. is a highly regarded company specializing in the production and distribution of aluminum extrusions. With a strong emphasis on quality, innovation, and customer satisfaction, C&C Manufacturing has established itself as a leading provider of aluminum extrusion solutions. At C&C Manufacturing, precision and excellence are at the forefront of their operations. Their team of skilled engineers and technicians utilizes advanced manufacturing processes and state-of-the-art equipment to produce aluminum extrusions of superior quality. With a keen attention to detail and a commitment to continuous improvement, they ensure that each extrusion meets the highest industry standards and customer expectations. C&C Manufacturing offers a comprehensive range of aluminum extrusion products to cater to diverse applications and industries. They provide both standard and custom profiles, allowing customers to select the most suitable shapes, sizes, and configurations for their specific needs. From simple angles and channels to complex geometries, C&C Manufacturing has the expertise and capabilities to deliver precise and intricate extrusions. The company's commitment to using high-quality materials is evident in their selection of premium-grade aluminum alloys. By sourcing alloys such as 6061 and 6063, which offer excellent strength, corrosion resistance, and thermal conductivity, C&C Manufacturing ensures that their extrusions are suitable for a wide range of applications. Whether it's for architectural projects, automotive components, electronics, or industrial machinery, their aluminum extrusions are engineered to deliver exceptional performance. In addition to their product offerings, C&C Manufacturing excels in providing comprehensive service capabilities. Their dedicated team works closely with customers to understand their specific requirements, offering valuable technical expertise and design assistance. From concept to completion, C&C Manufacturing supports customers throughout the entire process, ensuring efficient communication, timely delivery, and customer satisfaction. C&C Manufacturing places great importance on quality control to maintain the highest standards in their aluminum extrusion products. They employ rigorous testing and inspection procedures at every stage of production, ensuring dimensional accuracy, surface finish, and overall product reliability. Through their commitment to quality assurance, they strive to exceed customer expectations and build long-term relationships based on trust and reliability. The company's customer-centric approach extends beyond product manufacturing. C&C Manufacturing values open and transparent communication with their clients, fostering collaborative relationships built on trust and mutual understanding. They are responsive to customer inquiries, provide timely updates on project progress, and offer flexible solutions to meet unique requirements. Customer satisfaction is always their top priority. C&C Manufacturing is dedicated to environmental responsibility and sustainability. They actively seek ways to minimize waste, reduce energy consumption, and optimize their manufacturing processes to reduce their environmental impact. By embracing eco-friendly practices, they demonstrate their commitment to preserving the environment for future generations. In summary, C&C Manufacturing, Inc. is a respected provider of aluminum extrusion solutions. With their focus on precision, quality, and customer satisfaction, they offer a wide range of extrusion products tailored to meet diverse industry needs. Backed by comprehensive service capabilities, premium-grade materials, and a commitment to sustainability, C&C Manufacturing is a trusted partner for aluminum extrusion requirements, offering innovative solutions and exceptional customer service.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Nickel

Nickel Magnets

Magnets Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

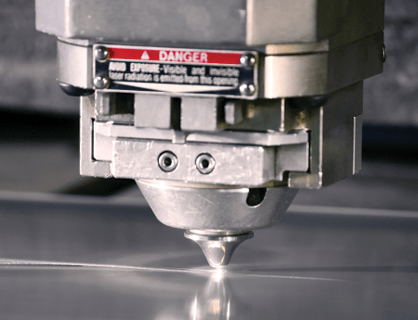

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

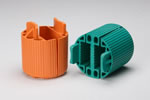

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services