Future Metals LLC

Future Metals LLCRequest A Quote

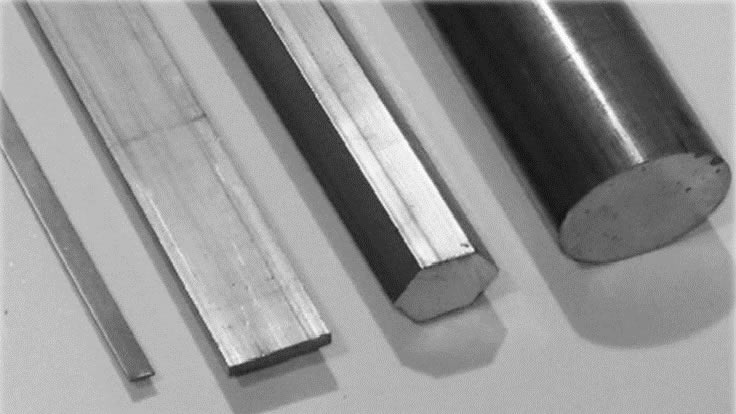

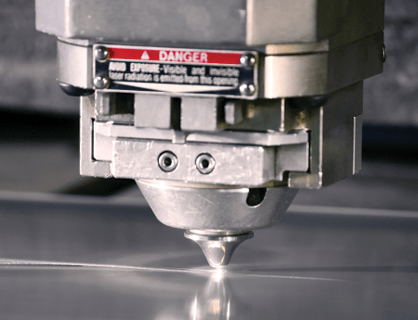

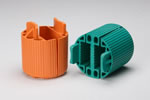

Tamarac, FL | 800-733-0960Future Metals LLC is a leading provider of aluminum extrusions, offering a comprehensive range of high-quality products and services to cater to the diverse needs of industries worldwide. With a strong commitment to innovation, reliability, and customer satisfaction, we have established ourselves as a trusted partner for aluminum extrusion solutions. Product Focus: Aluminum Extrusions Future Metals specializes in the design, manufacturing, and distribution of precision aluminum extrusions. Our extensive product portfolio includes: Standard Extrusions: We offer a wide selection of standard aluminum extrusions in various shapes, sizes, and alloys. These extrusions serve as versatile building components for a range of industries, including aerospace, defense, automotive, marine, construction, and more. Custom Extrusions: Our team of experienced engineers and designers works closely with clients to develop custom aluminum extrusions that meet their specific requirements. Utilizing advanced design software and state-of-the-art manufacturing processes, we transform concepts into highly precise and complex profiles, ensuring that our products meet the highest quality standards. High-Tolerance Extrusions: Future Metals specializes in producing high-tolerance aluminum extrusions that require tight dimensional tolerances, superior surface finishes, and precise geometries. These extrusions are utilized in critical applications where precision and quality are paramount. Specialty Extrusions: We offer specialty extrusions designed for unique applications, such as heat sinks, architectural features, transportation components, and more. These extrusions are engineered to meet specific functional and aesthetic requirements, showcasing our versatility and capability to provide customized solutions. Service Capabilities: Engineering and Design Support: Our skilled engineering team provides comprehensive engineering and design support to ensure optimal solutions for our customers. We offer expertise in material selection, extrusion design, tooling development, and manufacturability analysis. By collaborating closely with clients, we turn ideas into successful products. State-of-the-Art Manufacturing: Future Metals operates advanced manufacturing facilities equipped with state-of-the-art extrusion presses, precision cutting equipment, CNC machining centers, and quality control systems. This enables us to consistently produce aluminum extrusions of the highest quality, meeting stringent industry standards. Value-Added Services: We offer a range of value-added services to enhance the functionality and performance of our aluminum extrusions. These services include precision cutting, mitering, drilling, punching, CNC machining, welding, and assembly. We also provide a variety of surface treatments, such as anodizing, powder coating, and painting, to meet specific corrosion resistance or decorative requirements. Quality Assurance: At Future Metals, we maintain a rigorous quality management system to ensure that every product leaving our facility meets or exceeds customer expectations. Our dedicated quality control team conducts thorough inspections and tests to verify dimensional accuracy, mechanical properties, surface finish, and other critical parameters. Logistics and Global Distribution: We have a strong logistics network and global distribution capabilities, ensuring efficient and timely delivery of our products to customers worldwide. Our reliable supply chain solutions help meet project timelines and minimize downtime. Customer Support: We are committed to providing exceptional customer support and service. Our knowledgeable sales team is readily available to assist customers with product selection, technical inquiries, and order management. We strive to build long-term partnerships by delivering personalized solutions and exceeding customer expectations. Future Metals LLC is your trusted partner for high-quality aluminum extrusion solutions. With our extensive range of standard and custom extrusion profiles, engineering expertise, state-of-the-art manufacturing capabilities, comprehensive value-added services, and commitment to quality, we deliver innovative and reliable aluminum solutions for industries spanning aerospace, defense, automotive, and more. Count on Future Metals to provide you with exceptional products, technical support, and customer service that drive your success.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Nickel

Nickel Magnets

Magnets Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services