ILSCO Extrusions, Inc

ILSCO Extrusions, IncRequest A Quote

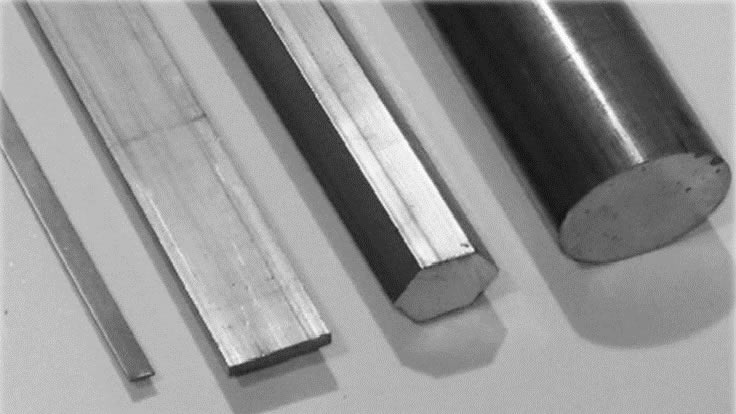

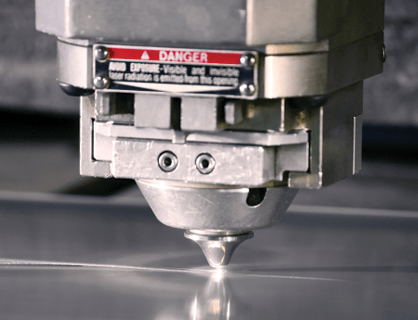

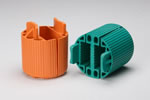

Greenville, PAILSCO Extrusions, Inc. is a leading manufacturer and supplier of high-quality aluminum extrusions, offering a comprehensive range of products and services. With a strong reputation for excellence and innovation, ILSCO Extrusions has been serving a diverse range of industries since its inception. Our commitment to providing top-notch aluminum extrusions has made us a trusted partner for companies in sectors such as construction, automotive, aerospace, electronics, transportation, and more. At ILSCO Extrusions, we pride ourselves on delivering solutions that meet the unique needs of our clients. Product Range: ILSCO Extrusions specializes in the production of precision aluminum extrusions that are known for their exceptional quality and durability. Our state-of-the-art manufacturing facilities are equipped with advanced extrusion presses, allowing us to produce a wide variety of shapes, profiles, and sizes. From simple to complex designs, we can customize extrusions to match the specific requirements of our customers. Our product range includes standard extrusions such as bars, rods, tubes, channels, angles, and beams. We also offer specialty extrusions, including heat sinks, window and door frames, automotive components, electronic enclosures, and more. ILSCO Extrusions provides both standard and custom extrusions, ensuring that we can accommodate a diverse array of applications. Service Capabilities: ILSCO Extrusions takes pride in offering comprehensive service capabilities to complement our exceptional product range. Our experienced team of engineers and technicians works closely with customers to understand their unique project requirements. We provide expert guidance throughout the entire process, from design and prototyping to production and finishing. Design and Engineering Support: We have a dedicated team of engineers who collaborate with customers to optimize their designs for efficient manufacturing. By leveraging our expertise, we help customers enhance the functionality, cost-effectiveness, and performance of their aluminum extrusion projects. Prototyping: ILSCO Extrusions understands the importance of prototyping in product development. We offer rapid prototyping services, enabling customers to evaluate the design and functionality of their extrusions before moving forward with large-scale production. Our quick turnaround times ensure that projects remain on schedule. Precision Manufacturing: With our advanced extrusion presses and skilled operators, ILSCO Extrusions ensures precise manufacturing of aluminum profiles. We adhere to strict quality control standards at every stage of production, guaranteeing consistency, accuracy, and superior surface finishes. Finishing Options: ILSCO Extrusions provides a range of finishing options to enhance the appearance and functionality of aluminum extrusions. Our capabilities include anodizing, powder coating, painting, polishing, and machining, allowing customers to achieve their desired aesthetics and corrosion resistance. Value-Added Services: In addition to extrusion manufacturing, we offer value-added services such as precision cutting, CNC machining, drilling, tapping, welding, and assembly. These services streamline the supply chain for our customers, reducing costs and lead times. Customer Support: ILSCO Extrusions is committed to delivering exceptional customer service. Our dedicated customer support team is readily available to address inquiries, provide technical assistance, and ensure a seamless experience throughout the entire project lifecycle. ILSCO Extrusions is a trusted partner for companies seeking high-quality aluminum extrusions. With our extensive product range, cutting-edge manufacturing capabilities, and comprehensive service offerings, we strive to exceed customer expectations and contribute to their success.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Nickel

Nickel Magnets

Magnets Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services