Johnson Bros. Roll Forming Co.

Johnson Bros Roll Forming CoRequest A Quote

Berkeley, IL | 708-449-7050https://www.rollformingpro.com/

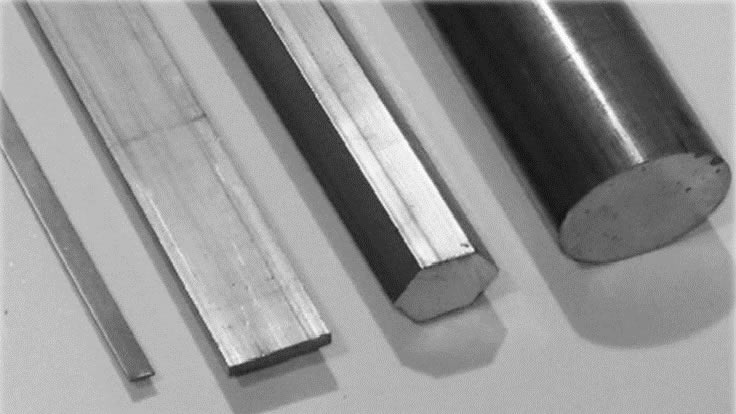

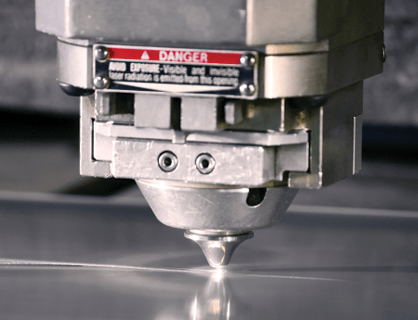

Johnson Bros. Roll Forming Co. is a reputable company specializing in the production of aluminum extrusions through the process of roll forming. With a rich history spanning several decades, Johnson Bros. has established itself as a leader in the industry, offering a wide range of high-quality aluminum extrusion products and exceptional service capabilities. At Johnson Bros., the roll forming process is employed to produce aluminum extrusions with precise shapes, dimensions, and consistent quality. Their state-of-the-art manufacturing facility is equipped with advanced roll forming machines and tooling, allowing them to create complex and custom-designed profiles. The roll forming process ensures excellent dimensional accuracy, tight tolerances, and consistent part quality across large production volumes. The company offers a diverse range of aluminum extrusion profiles to cater to various industries and applications. Their product catalog includes standard profiles such as angles, channels, Z-sections, C-sections, and T-sections, as well as custom-designed profiles tailored to meet specific customer requirements. These profiles are available in different alloys, including 6061, 6063, and 3003, offering excellent strength, durability, and corrosion resistance properties. Johnson Bros. is known for its expertise in providing value-added services to enhance the functionality and versatility of their aluminum extrusion products. They offer a comprehensive range of secondary operations, including cutting, punching, notching, embossing, and hole punching. These services enable customers to receive fully fabricated or semi-finished aluminum extrusions that are ready for immediate use in their applications. With a focus on customer satisfaction, Johnson Bros. places great importance on understanding the unique needs of their clients. Their experienced engineering team works closely with customers to develop custom extrusion designs, optimize product performance, and provide cost-effective solutions. They offer design assistance and collaborate closely with customers throughout the entire process, from concept development to final production, ensuring that the extrusion meets the desired specifications and functional requirements. Quality is a top priority at Johnson Bros. They follow strict quality control procedures at every stage of production, starting from the selection of raw materials to the final inspection of finished products. Their quality assurance team conducts rigorous testing and inspections to ensure that each aluminum extrusion meets the highest industry standards for dimensional accuracy, surface finish, and overall performance. Johnson Bros. is committed to providing exceptional customer service and support. Their knowledgeable sales team is dedicated to assisting customers with their inquiries, providing technical guidance, and offering prompt responses to ensure a seamless ordering process. With a focus on open communication, reliability, and on-time delivery, Johnson Bros. strives to exceed customer expectations and build long-term partnerships. In summary, Johnson Bros. Roll Forming Co. is a trusted provider of aluminum extrusion products and services, offering a wide range of profiles, value-added capabilities, and exceptional customer support. With their expertise in roll forming, commitment to quality, and dedication to customer satisfaction, they are well-positioned to meet the unique needs of various industries. Johnson Bros. Roll Forming Co. is a reliable partner for aluminum extrusion solutions, delivering products of superior quality, precision, and functionality.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Nickel

Nickel Magnets

Magnets Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services