Leed/Himmel Industries, Inc.

Leed/Himmel Industries, Inc.Request A Quote

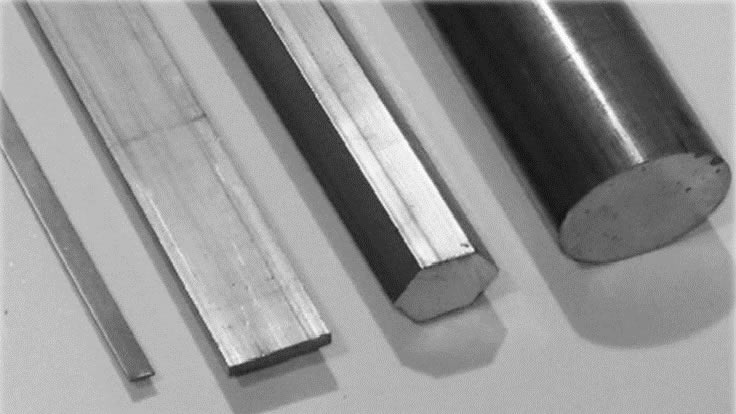

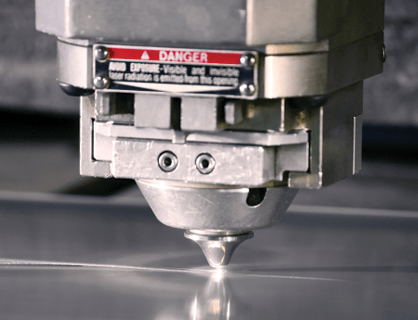

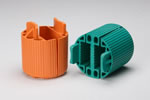

Hamden, CTLeed Himmel Industries Inc. is a leading provider of high-quality aluminum extrusions for a wide range of industries. With over 30 years of experience in the industry, Leed Himmel has become a trusted partner to many customers, providing custom solutions that meet their unique needs. Leed Himmel's aluminum extrusions are used in a variety of applications, including construction, transportation, automotive, and consumer products. The company's extrusion capabilities include the production of standard and custom shapes, sizes, and alloys, with the ability to extrude up to 10-inch diameter shapes. The company's state-of-the-art facilities are equipped with the latest technology and equipment, allowing for precision extrusions with tight tolerances. Leed Himmel's experienced team of engineers and technicians work closely with customers to ensure that their designs are optimized for manufacturability and cost-effectiveness. In addition to aluminum extrusions, Leed Himmel offers a range of value-added services, including cutting, drilling, bending, and finishing. The company's finishing capabilities include anodizing, powder coating, and painting, providing customers with a one-stop-shop for their aluminum extrusion needs. Leed Himmel is committed to providing exceptional customer service and quality products. The company is ISO 9001:2015 certified, demonstrating its commitment to quality management systems and continuous improvement. Overall, Leed Himmel Industries Inc. is a reliable and innovative provider of aluminum extrusions and value-added services. With its dedication to quality and customer service, Leed Himmel is a trusted partner to many customers across various industries.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Nickel

Nickel Magnets

Magnets Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services