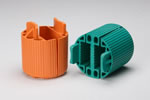

A T-slot aluminum extrusion is an aluminum bar that has been shaped, or extruded, into slotted profiles either by using the squeezing method or by making use of a die. A T-shaped T-slot aluminum extrusion can be used for various structural and framing applications. The distinctiveness of a T-slot extrusion lies in the fact that its various components can be put together without using specialized tools or welding. Read More…

Since 1948, Johnson Brothers has been a leader in the aluminum roll forming industry. Our tooling can form different shapes with multiple bends & double thicknesses making a stronger part. Choose your type of outside edge, including hemmed designs. Our manufacturing procedure can take your part from concept to achievement. Please contact us today with any questions.

Quality Stamping & Tube Corp has been a leader in the aluminum extrusions and metal stamping industries for over 40 years. We attribute our success to our in-house die-making capabilities and wide range of extruded parts. All of our products are manufactured with quick turnaround and made to be high quality and durable. Our aluminum extrusions follow guidelines of up to 6 inches in diameter and...

Since 1986, GSH Industries has offered on time delivery and competitive pricing. With over 40,000 square feet of manufacturing, we offer aluminum extrusion products and services.

Dajcor Aluminum is the leading North American supplier of extruded, fabricated/machined, anodized and assembled components to the automotive, renewable energy, transportation, rail, marine, building trades, military, medical architectural and wall partition systems, office furniture, emergency vehicle and consumer product industries. Dajcor is an aluminum extrusion company with complete value add ...

More T-Slot Aluminum Extrusion Manufacturers

This modular channeled aluminum makes it simple to join and combine with other aluminum components without welding or clamping. T-slot aluminum extrusions don't require polishing; they already have a beautiful aesthetic finish. In addition, aluminum with T-slots is sturdy and resistant to corrosion.

Manufacturing Processes of T-Slot Aluminum Extrusions

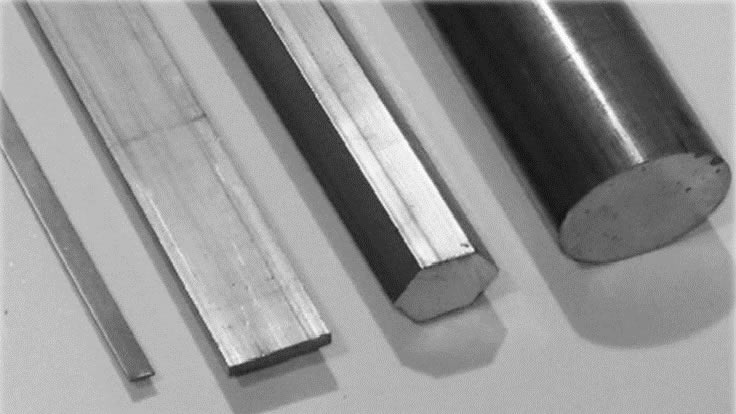

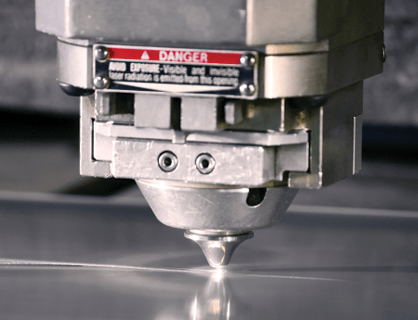

There are two methods used to create T-slot aluminum extrusions. One method uses a die and the other involves more of a “squeezing” process. We examine these processes below in further detail.

Die Method

A huge hydraulic ram, a massive aluminum rod, and a die are needed for this process. The hydraulic ram subjects the aluminum rod to enormous pressure as it forces the rod through the die. The most crucial step in the extrusion process is likely in the die’s design. Dies must keep their dimensional stability while withstanding powerful forces at high temperatures. Extrusion dies are round forms of steel- usually around a foot (30 centimeters), but sometimes up to a yard (meter), in diameter.

Dies are often rather thin in profile compared to their diameter since the longer the distance the aluminum takes passing through the die, the more force required to press the material through, and the more friction it experiences. Any increase in friction creates more die wear, and generally higher costs.

The Squeeze Casting Method

When employing the squeeze method, a sizable length of aluminum, also known as a billet, is heated using an induction heater or a gas furnace. It's vital to remember that this billet is not melted, only softened and that the heater’s temperature will fluctuate depending on the particular alloy and the complexity of the die. The die and a large portion of the hydraulic press are also heated to avoid thermal stresses from damaging any of the equipment and to stop the aluminum from cooling too quickly and sticking to the die.

Most horizontally-oriented aluminum extrusion presses have a large hydraulic ram with a small gap between it and the die. After inserting the heated billet into that opening, the hydraulic ram begins pressing it into the die (or, in indirect extrusion, moves the die over the material). As the metal exits the die, it starts to flow into the die's gaps, and narrows down into its final T-slot shape.

Applications of T-Slot Aluminum Extrusions

- Machine bases and enclosures: Aluminum T-slots can be used for machine bases and enclosures because they are easy to assemble, and they have light weight.

- Carts for moving various materials: The T-slot can offer a stronger and more durable design when compared to other materials such as painted steel, wood, or plastic. Depending on the design, aluminum utility carts can be either stationary or equipped with caster or swivel wheels.

- Ladder making: Aluminum T-slots are used in the making of ladders because their lightweight and T-slotted legs offer stability.

- Architectural elements like roofs, sign frames, and window and door frames: T-slot aluminum extrusions provide several advantages when used as window framing. They provide excellent strength and weight support. Additionally, these extrusions are simple to convert into window frames, which saves time and money. Serving as window frames, T-slot aluminum extrusions provide flexibility that is unmatched by similar materials.

Advantages of T-Slot Aluminum Extrusions

- Aluminum T-slot extrusions are adaptable and can be used to make numerous items and a welder and welding equipment are typically not required during conversion.

- Aluminum T-slot extrusions are robust and long-lasting.

- T-slot aluminum extrusions are easy to assemble.

- T-slot aluminum is corrosion-resistant and low in weight.

- The versatility of T-slot aluminum extrusions provides a less expensive solution for creating items.

- According to the ergonomic safety inspectors' advice, the product is safe to use.

- T-slot aluminum extrusions feature a nice finish.

In summary, work can be done more quickly, adjustments can be made more easily, and production costs can be reduced by using T-slot aluminum extrusions.

Disadvantages of T-Slot Aluminum Extrusions

T-slot aluminum extrusions provide inconsistent performance. The surface layer, center, head, and tail of these extruded products are not uniform because the flow of metal is not uniform during the extrusion process. This is particularly serious when there is no lubricating forward extrusion.

The extrusion die's operating environment is demanding and prone to wear and tear. The aluminum blank that undergoes extrusion is under strong three-way pressure and nearly closed during extrusion. The strength and service life of the molds used to create T-slot aluminum extrusions are significantly impacted by the high temperature, and high friction often applied to them during the hot extrusion process used to create them.

The extrusion process can be time-consuming and cannot provide a consistent production rate. Extrusion speeds are often significantly slower than other processes used to create aluminum items, such as rolling. Rolling is a process where a metal block is passed through one or more pairs of rolls during the rolling process in order to reduce thickness, make thickness uniform, and/or impart a desired mechanical quality.

Choosing the Correct T-Slot Aluminum Extrusions Manufacturer

To make sure you have the most beneficial outcome when purchasing T-Slot Aluminum Extrusions from a T-Slot Aluminum Extrusions Manufacturer, it is important to compare at least 4 or 5 Suppliers using our list of T-Slot Aluminum Extrusions companies. Each T-Slot Aluminum Extrusions Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each T-Slot Aluminum Extrusions company website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple T-Slot Aluminum Extrusions businesses with the same form.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Nickel

Nickel Magnets

Magnets Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services